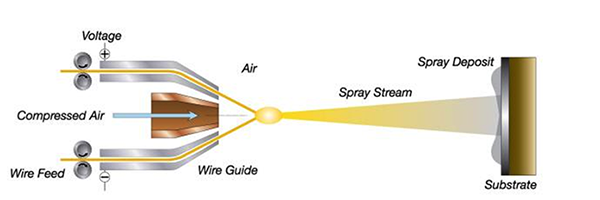

Twin arc spray coating, also known as wire arc spray, is a thermal spray technique that enhances the durability of industrial components by applying robust metallic coatings. It uses an electric arc to melt two conductive wires. Compressed air atomizes and propels molten particles onto a substrate. Twin arc is often more cost-effective and suited for large-scale applications, offering corrosion resistance, wear protection, and dimensional repair. Unlike high-energy processes such as plasma or HVOF, it prioritizes affordability and simplicity. Making it ideal for industries such as infrastructure, marine, and manufacturing.

Common Materials Used

- Zinc: Sacrificial corrosion protection for bridges, pipelines, and marine structures.

- Aluminum: Lightweight, corrosion-resistant coatings for ship hulls and chemical plants.

- Zinc-Aluminum Alloy: Combines corrosion resistance and durability for structural steel and wind turbines.

- Stainless Steel: Wear and corrosion resistance for machinery and pump shafts.

- Nickel-Chromium Alloys: High-temperature resistance for boiler tubes and turbines.

- Copper: Enhances electrical conductivity for bus bars and connectors.

- Bronze: Reduces friction in bearings and marine hardware.

Applications of Twin Arc Coatings

- Corrosion Protection: Zinc or aluminum coatings shield bridges, pipelines, offshore platforms, and ship hulls from rust and saltwater corrosion.

- Dimensional Restoration: Low-carbon or stainless steel coatings rebuild worn parts like crankshafts and hydraulic cylinders.

- Electrical Conductivity: Copper coatings enhance performance in electrical connectors and bus bars.

- High-Temperature Resistance: Nickel-chromium coatings protect boiler tubes and turbines from heat and oxidation.

Twin arc excels in large-scale, cost-sensitive projects compared to other higher energy coating processes.

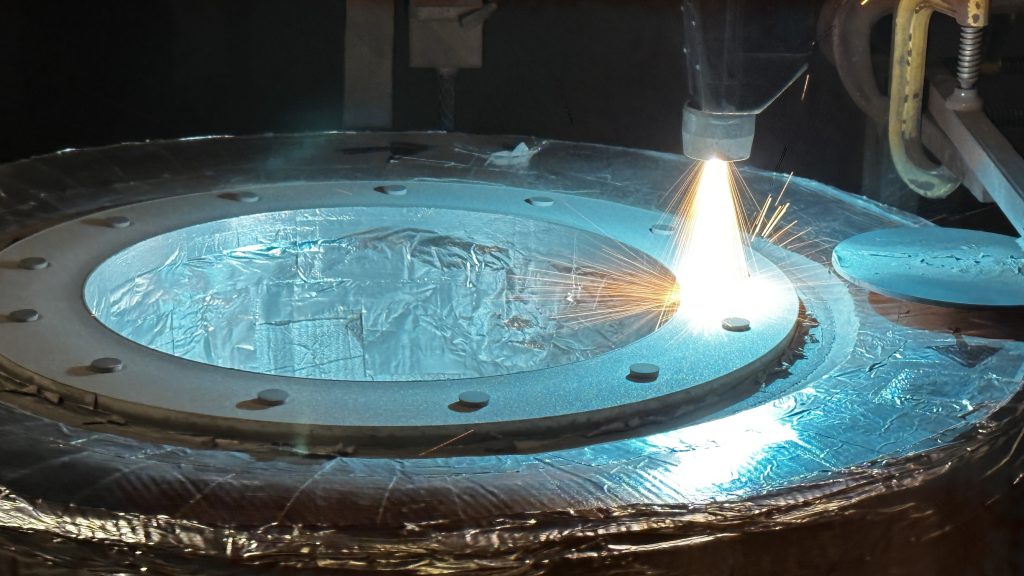

Longevity Coatings’ Expertise in Twin Arc Spray

Longevity Coatings delivers superior twin arc spray coatings using a state-of-the-art, computer-controlled system that ensures precision and consistency. This setup combines precisely controlled spray head air pressure with an automated spray rate, producing high-density coatings with excellent bond strength for applications like corrosion protection and dimensional restoration. Longevity Coatings applies durable coatings to components like bridges, pipelines, and machinery parts, offering cost-effective solutions compared to high-energy processes like plasma or HVOF. Our expertise ensures repeatable, high-quality coatings that enhance component longevity in industry.