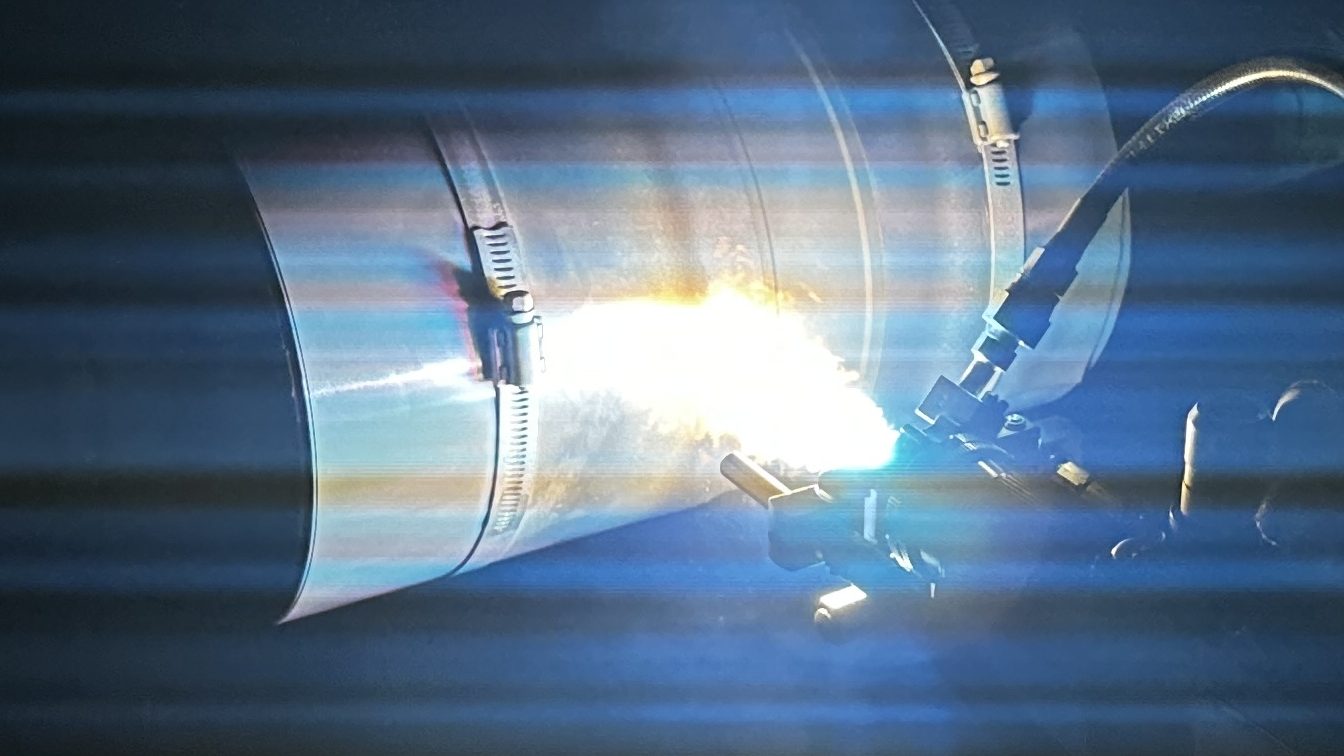

Advanced Plasma Coatings for Superior Performance

Our non-transferred arc plasma coating process delivers unmatched precision and durability. In this advanced technique, an arc is generated between an electrode and a constricting nozzle, creating a high-energy plasma that ionizes the gas stream. This intense heat, reaching up to 30,000°F, melts and propels high-performance coating materials onto the workpiece. Forming robust plasma coatings ranging from a few micrometers to several millimeters thick.

Versatile Applications of for Industry Excellence

- Clearance Control: Abradable coatings optimize efficiency in rotating machinery like gas turbines by ensuring precise clearance control under extreme conditions.

- Energy Sector Equipment: Components in power generation systems, such as boiler tubes or wind turbine parts, benefit from resistance to heat and corrosion.

- Semiconductor Manufacturing: Plasma coatings on wafer processing equipment enhance durability against chemical exposure and high temperatures.

- Thermal Barrier Coatings for High-Temperature Protection: These coatings can serve as thermal barriers on components like gas turbine blades, engine parts, and industrial furnace linings, shielding them from extreme heat while maintaining structural integrity and enhancing operational efficiency.

- Valve Parts for Enhanced Durability and Performance: Protect valve components in automotive, oil and gas, and industrial systems from corrosion, wear, and high temperatures, ensuring reliable operation, extended service life, and reduced maintenance in demanding environments.

- Inert Coatings for Extreme Chemical Resistance: Provide highly inert surfaces for components in chemical processing, semiconductor manufacturing, and medical equipment, resisting corrosion and degradation in harsh, reactive environments while ensuring long-lasting performance and safety.

High-Performance Plasma Coatings for Extreme Applications

Longevity specializes in applying high-melting-point materials like chromium oxide, aluminum oxide, ceramics, and refractory materials, making our plasma coatings ideal for demanding applications. Additionally, our process excels in creating unique abradable coatings for clearance control in rotating machinery, ensuring optimal performance and longevity. Choose Longevity Plasma for cutting-edge plasma coatings that enhance durability and precision in every project.

Get Started with Expert Plasma Coatings

Longevity Coatings delivers durable, high-performance solutions tailored to your industry’s needs. Discover how our advanced plasma coatings can boost efficiency and longevity for your applications. Visit our contact page or call us now to discuss your project.