Oxide Ceramic Coatings: Engineering Superior Surfaces

Oxide ceramic coatings are advanced inorganic coatings. They are made from metal oxides like aluminum oxide (Al₂O₃), zirconium oxide (ZrO₂), chromium oxide (Cr₂O₃), and titanium dioxide (TiO₂). They are applied to substrates, primarily metals, to enhance surface properties. These include wear resistance, corrosion protection, thermal insulation, electrical insulation, and chemical stability.

Common oxide ceramics for coatings

- Aluminum Oxide (Al₂O₃)

- High hardness, wear and corrosion resistance, electrical insulation.

- Zirconium Oxide (ZrO₂)

- Excellent thermal barrier, high toughness, chemical stability.

- Chromium Oxide (Cr₂O₃)

- Superior wear and chemical resistance, high hardness.

- Titanium Dioxide (TiO₂)

- Moderate wear resistance, good lubricity, photocatalytic properties.

- Often blended with other oxide ceramic coatings

- Yttrium Oxide (Y₂O₃)

- High thermal and erosion resistance, chemical stability.

There are many more that are commonly used in the thermal spray coating industry. They are often blended together to provide different properties.

Key Properties

- Corrosion Resistance: Protects against chemical and environmental degradation, suitable for harsh conditions like marine or industrial settings.

- Thermal Barrier: Low thermal conductivity (e.g., zirconia) enables use in high-temperature environments like turbine blades and engine components.

- Electrical Insulation: Alumina coatings provide dielectric strength (300–400 volts per 0.001” thickness), used in motor housings and non-conductive rollers.

- Chemical Stability: Resists acids, alkalis, and other corrosive substances, though performance varies (e.g., titanium dioxide is less resistant to alkalis).

- Wear Resistance: High hardness (e.g., chrome oxide at 62–70 Rockwell C) makes these coatings ideal for resisting abrasion and erosion.

Application Method

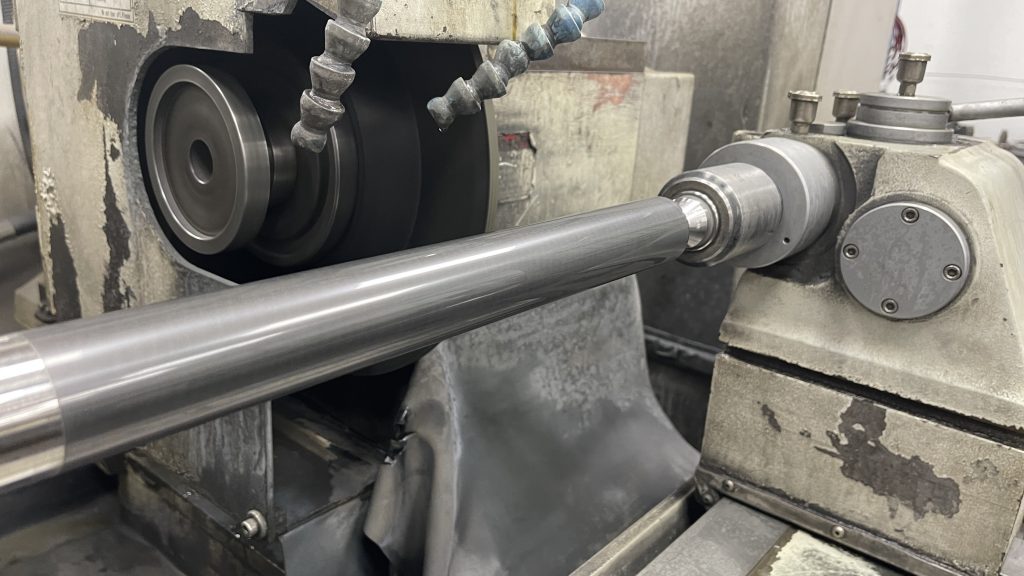

At Longevity Coatings, we harness plasma spray technology to deliver high-performance oxide ceramic coatings that extend the life of your components. Our advanced process ensures durable, precision-engineered coatings tailored for the toughest industrial challenges.

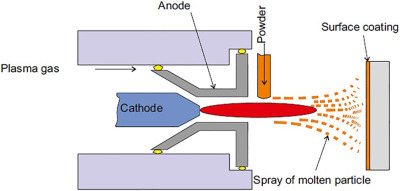

What Is Plasma Spray?

Plasma spraying uses a high-temperature plasma jet (12,000–35,500°F) to melt and apply oxide ceramic materials. Such as aluminum oxide (Al₂O₃), zirconium oxide (ZrO₂), and chromium oxide (Cr₂O₃), onto surfaces. The result is a dense, strongly bonded coating that enhances wear resistance, corrosion protection, and thermal insulation.

Our Process

- Precision Preparation: We clean and roughen surfaces to ensure optimal coating adhesion.

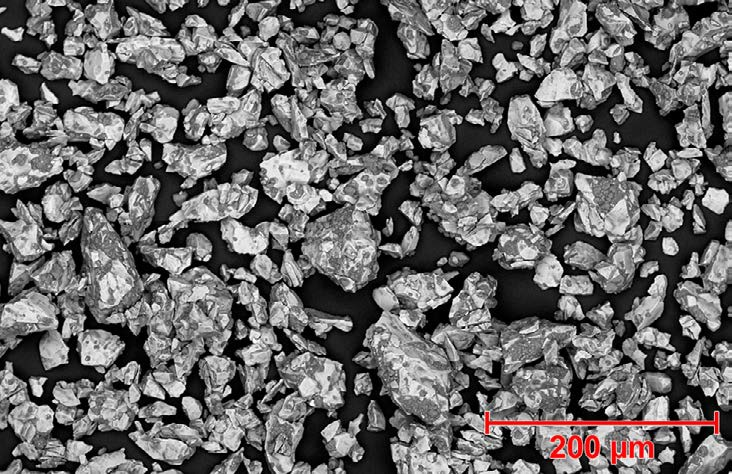

- Tailored Material Selection: We choose premium oxide ceramics, like Alumina for wear resistance or ZrO₂ for thermal protection, based on your application.

- Advanced Plasma Spraying: Our State of the art equipment melts ceramic powders in a plasma jet, creating a uniform, high-density coating.

- Custom Finishing: We diamond grind, Lap, or super finish coatings to your exact specifications, achieving the best finish possible.

Applications For Oxide Ceramic Coatings

Longevity Coatings serves industries with precision-engineered solutions

- Energy Sector Components

- Steel and Metal Processing

- Industrial Pump and Seal Systems

- Aerospace Components

- Many More

Why Partner with Longevity Coatings?

With decades of expertise in plasma spray technology, Longevity Coatings delivers ceramic coatings that meet the highest industry standards. Our commitment to quality and innovation ensures your components perform better and last longer, even in the harshest conditions.

Ready to enhance your components?

Contact Longevity Coatings today to discover how our plasma-sprayed oxide ceramic coatings can transform your project!