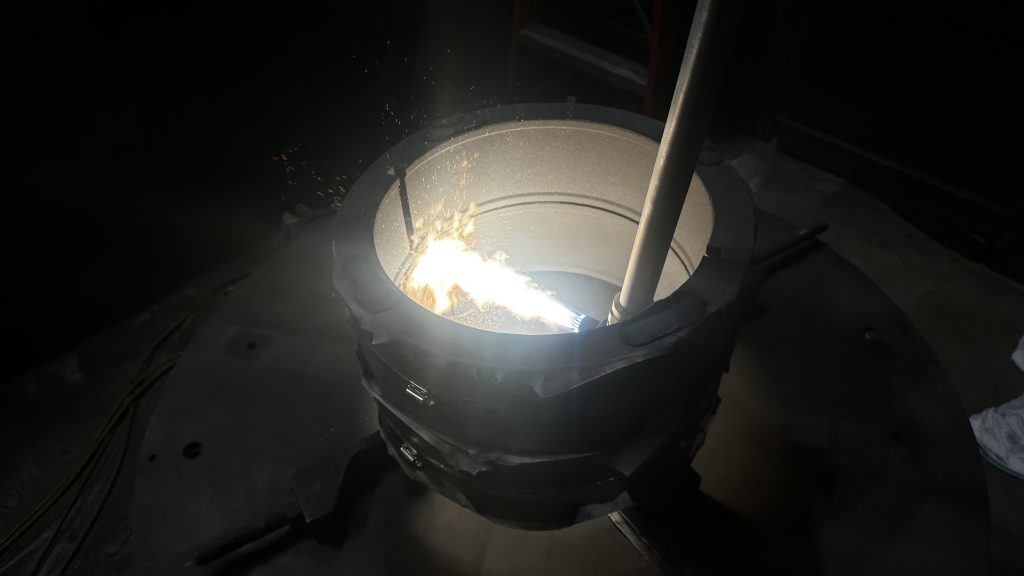

Abradable coatings are a specialized technology that might not grab headlines, but they play a vital role in boosting performance, cutting costs, and improving sustainability across various industries. They are typically applied with the plasma spray process or combustion flame spray. These coatings are designed to wear away in a controlled manner when they come into contact with moving parts, which sounds counterintuitive but delivers some impressive benefits. Below is a rundown of what abradable coatings are and how they make a difference in industrial applications.

What Are Abradable Coatings?

Abradable coatings are materials applied to surfaces in machinery, particularly in areas with high friction or tight clearances—like turbine seals, compressor seals, or pump components. Unlike traditional coatings meant to endure, these are engineered to wear down slightly when rubbed against moving parts. This controlled wear creates a custom fit, allowing machinery to operate with minimal gaps while protecting expensive components from damage. Think of them as a sacrificial layer, similar to brake pads in a car that wear down to save the rotors.

Key Benefits for Industry

Abradable coatings offer a range of advantages that make them invaluable in industrial settings. Here’s how they help:

– Improved Efficiency

In machinery like turbines, engines, or compressors, small gaps between moving parts can lead to leaks of gas or fluid, reducing performance. Abradable coatings enable tighter clearances by wearing just enough to form a perfect seal. This minimizes leakage, increases pressure ratios, and makes systems more energy-efficient—crucial for industries where every percentage point of efficiency translates to big savings.

– Cost Savings

These coatings take the brunt of the wear, protecting pricier parts from damage. This reduces the need for frequent repairs or replacements, lowering maintenance costs. Add in the energy savings from improved efficiency, and the financial benefits stack up quickly.

– Longer Equipment Life

By sparing critical components from wear and tear, abradable coatings extend the lifespan of machinery. This means less downtime for repairs and fewer full replacements, which is a game-changer for industries relying on continuous operation.

– Enhanced Safety

In high-speed or high-temperature environments, metal-to-metal contact can spark catastrophic failures. Abradable coatings prevent this by acting as a buffer, reducing risks and keeping operations safe and reliable.

– Environmental Impact

Efficiency isn’t just about profit—it’s also about sustainability. By cutting fuel consumption and emissions through better performance, abradable coatings help industries meet environmental goals without compromising output.

Where Are They Used?

Abradable coatings shine in industries where precision, durability, and efficiency are non-negotiable. Some key examples include:

- Aerospace: Jet engines use these coatings in turbine seals to boost fuel efficiency and reliability while cutting emissions.

- Power Generation: Gas and steam turbines rely on them to optimize performance and prolong component life.

- Automotive: Turbochargers and high-performance parts benefit from their ability to handle tough conditions efficiently.

- Manufacturing: Rotating machinery like pumps and compressors use them to reduce wear and improve uptime.

Why Abradable Coating Matters

Abradable coatings may be a small detail in the grand scheme of industrial tech, but their impact is outsized. They improve how machines run, save money on maintenance and energy, and even help the planet by reducing waste and emissions. For industries like aerospace, power generation, and manufacturing, they’re a quiet but powerful tool to stay competitive and sustainable.

In short, abradable coatings are a smart, practical solution that deliver big results—proof that sometimes the smallest upgrades can make the biggest difference.

Why Choose Longevity Coatings?

When it comes to enhancing the durability and performance of industrial equipment, Longevity Coatings stands out. We Specialize in advanced thermal spray coatings, We offers a range of benefits that make it a preferred partner for businesses across various industries.