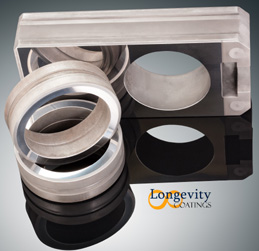

Longevity Coatings develops proprietary process for flat surface finishing of wellhead valve components

Longevity Coatings, based in Allentown, PA, has developed a proprietary coating process that achieves surface flatness down to 12 millionths of an inch and finishes finer than 1Ra. Designed for valve components in oil and gas wellhead equipment, this breakthrough extends service life significantly compared to competitors and even Original Equipment Manufacturers (OEMs), according to Mark Purington, owner and general manager.

Wellhead valves are vital for controlling oil or gas flow under extreme pressures—up to 20,000 psi. A failure here risks catastrophic blowouts. Critical components like sliding slab gates and sealing rings rely on metal-to-metal contact, demanding perfectly flat surfaces to prevent leaks without non-metallic seals.

Longevity’s process refurbishes worn slab gates and seats at roughly one-third the cost of new components. “We strip old coatings, apply high-quality tungsten carbide, and use our proprietary flat-finish process to deliver scratch-free surfaces that meet or exceed OEM standards,” Purington explains. The result: coatings with 12 millionth-inch flatness and sub-1Ra finishes, ensuring superior performance and durability.

While wellhead service contractors are the primary market, Purington sees potential for OEMs to leverage this technology to enhance new valve components. Longevity’s Allentown facility is equipped to handle diverse applications, with systems capable of coating parts up to 18 feet long and 50 inches in diameter. Advanced multi-axis, computer-controlled systems ensure precision for shafts, sleeves, plungers, valves, and more.

For oil and gas operators seeking cost-effective, high-performance valve solutions, Longevity Coatings offers unmatched quality and longevity. Learn more about how this process can optimize your operations at by phone, email, or our contact forum