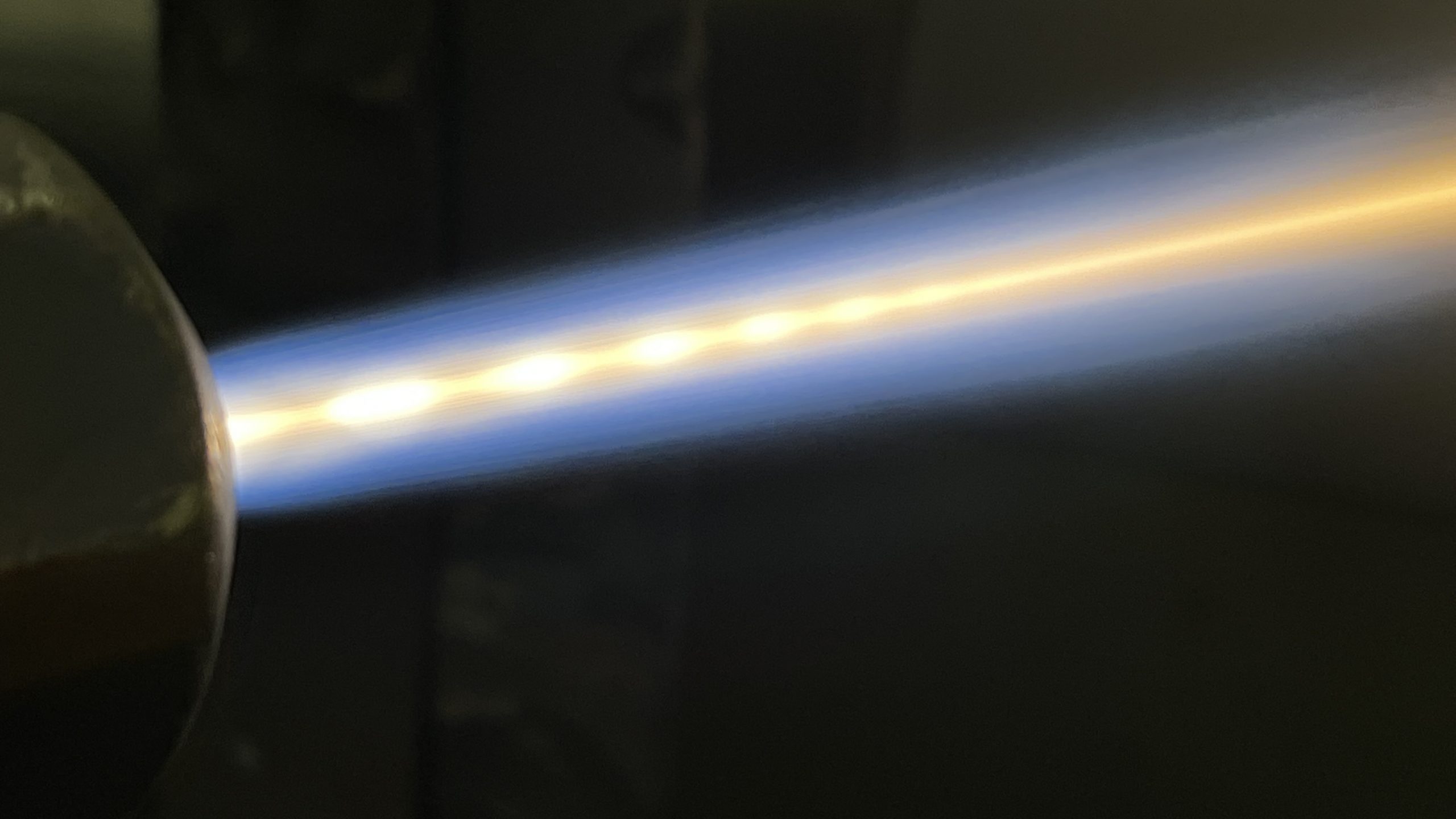

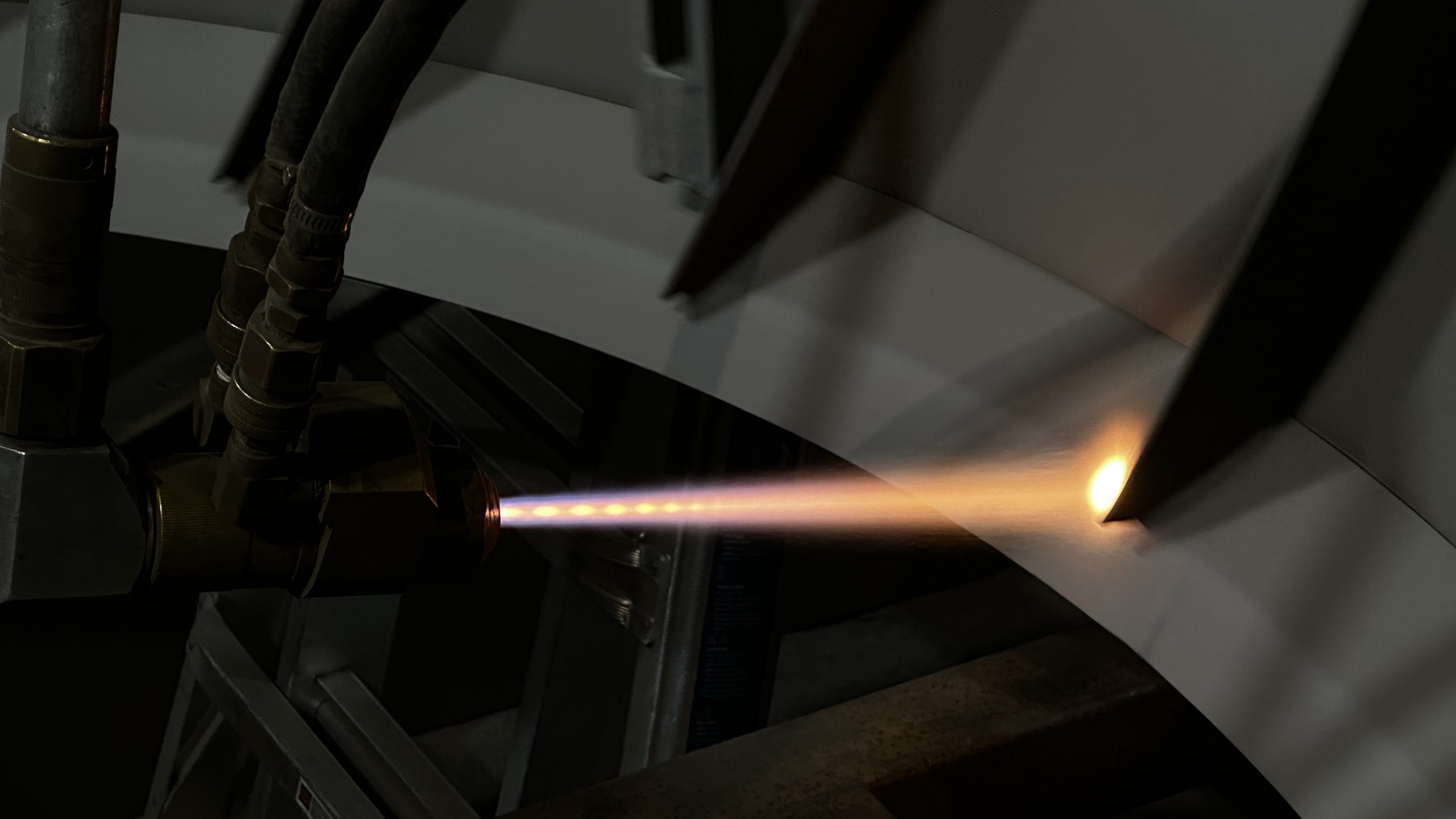

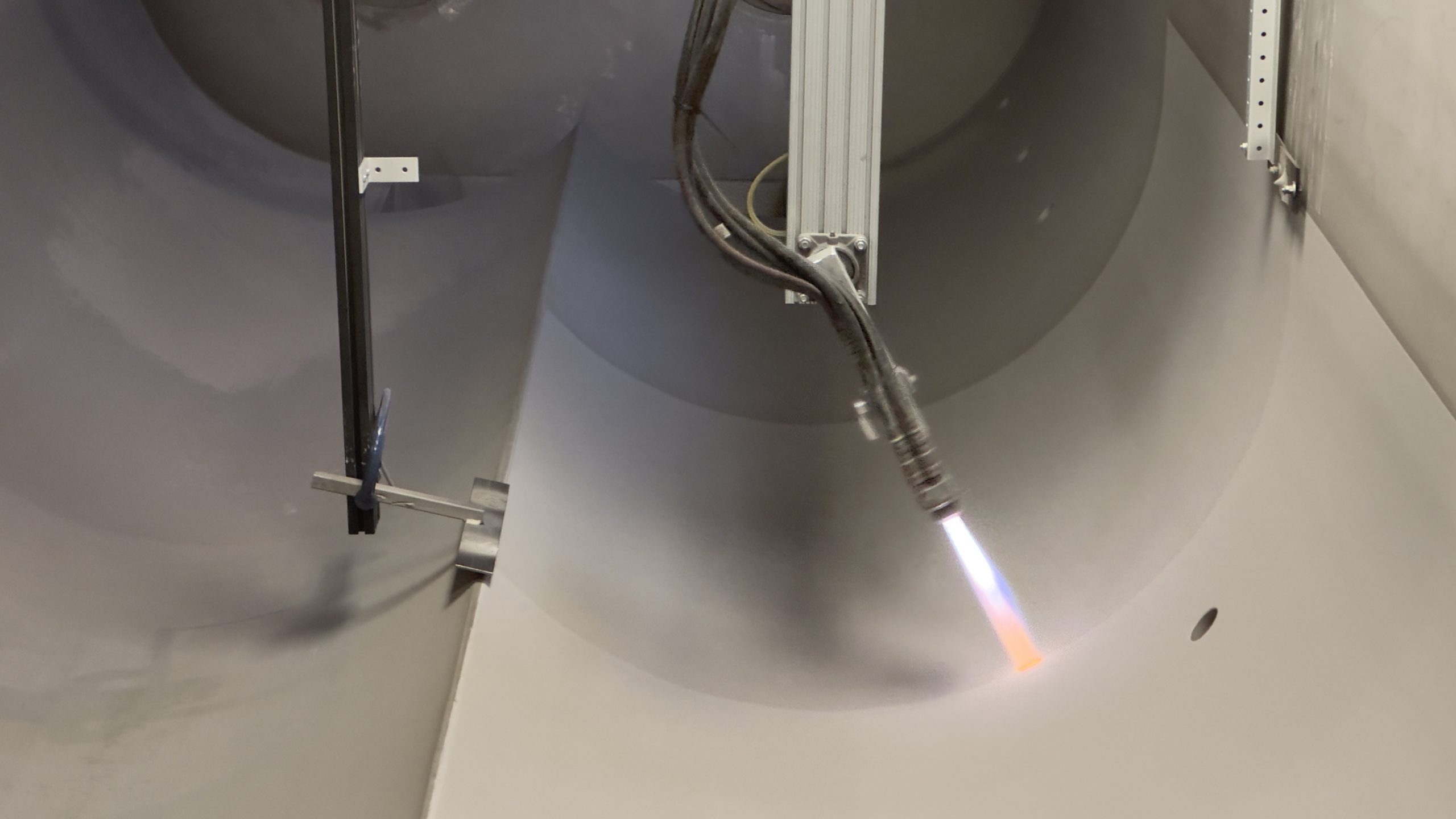

High-Velocity Oxygen Fuel (HVOF) coating is a thermal spray process that applies exceptionally durable and high-quality coatings to surfaces. The process works by accelerating a mixture of oxygen and fuel through a specially designed nozzle. This generates a supersonic jet that propels coating materials at extreme velocities onto the target surface. This high-speed application produces coatings that are remarkably dense. They contain significantly less oxide content than those created by other thermal spray methods. As a result, HVOF coatings deliver outstanding resistance to wear and corrosion, providing long-lasting protection even in harsh industrial environments. For industries seeking reliable and enduring surface solutions, it is industry standard.

At Longevity Coatings, we specialize in providing top-tier HVOF solutions. With decades of experience and a commitment to quality, we ensure that every coating meets the highest standards of performance and durability.

Benefits of HVOF Coatings

Our HVOF coating services offer a range of advantages:

- Superior Wear Resistance: The high-velocity application ensures a strong bond, making HVOF coatings perfect for demanding environments.

- Low Porosity: hvof coatings have lower porosity than other thermal spray processes.

- Corrosion Resistance: Shield your components from harsh conditions.

- Material Versatility: Compatible with metals, alloys, and carbides.

- Lower oxygen content: The coating has lower oxygen content. Due to the short dwell time and relatively low temperatures reduce oxidation during the process.

Common Materials

- Tungsten Carbide (WC-Co, WC-Co-Cr)

- It is Ideal for high-wear environments, extending part life significantly.

- Chromium Carbide (Cr₃C₂-NiCr)

- Properties: High-temperature oxidation resistance (up to 1,600°F), excellent corrosion and wear resistance.

- Perfect for high-temperature, corrosive environments requiring durability. Particularly in hard chrome replacement.

- Nickel-Based Alloys

- Properties: Strong corrosion resistance, good bonding strength, moderate hardness.

- Provides a cost-effective solution for corrosion-prone environments.

- Cobalt-Based Alloys

- Properties: Excellent wear resistance, high toughness, and corrosion resistance.

- Balances toughness and durability for critical, high-stress components.

- Stainless Steels

- Properties: Strong corrosion resistance, moderate hardness, high toughness.

- Cost-effective for corrosion-prone environments requiring durability. Extensively used in dimensional repairs.

Why Choose Longevity Coatings?

- Expertise: Years of experience in HVOF thermal spray technology.

- Advanced Technology: Cutting-edge equipment for top-quality HVOF coatings.

- Tailored Solutions: Customized HVOF coating options to meet your needs.