Introduction to Tungsten Carbide Coatings

Thermal sprayed tungsten carbide coatings are protective layers applied to surfaces using high-velocity thermal spray processes like HVOF (High-Velocity Oxygen Fuel), HVAF (High-Velocity Air Fuel), or plasma spraying. In these processes, tungsten carbide powder is heated and propelled at high speeds onto a substrate, forming a dense, hard coating. Tungsten carbide coating offers exceptional benefits, including superior wear resistance, high hardness (often exceeding 1200 HV), and excellent corrosion resistance, making them ideal for harsh environments. They significantly extend the lifespan of components, reduce maintenance costs, and enhance performance.

Types of Carbide Materials for Coatings

- WC-CO

- Consists of tungsten carbide particles in a cobalt binder (typically 6-20% cobalt). The cobalt provides toughness and adhesion to the substrate.

- Extremely high hardness carbide coating (~1000-1500 HV), excellent abrasion and sliding wear resistance, and good toughness due to the cobalt binder. Moderate corrosion resistance, suitable for temperatures up to ~500°C.

- Superior wear resistance and toughness make it ideal for demanding environments where abrasion and impact are primary concerns. Cost-effective and widely used across industries

- WC-NI

- Uses nickel as the binder instead of cobalt, with similar tungsten carbide content. Nickel enhances corrosion resistance in specific environments

- High hardness (~900-1200 HV), slightly lower than WC-Co, with excellent corrosion resistance in acidic or saline environments. Good wear resistance and moderate toughness, stable up to ~600°C.

- Enhanced corrosion resistance compared to WC-Co, making it suitable for harsh chemical or saline conditions while maintaining strong wear resistance.

- WC-CO-CR

- Combines cobalt and chromium as binders (e.g., WC-10Co-4Cr), offering a blend of cobalt’s toughness and chromium’s corrosion and oxidation resistance.

- High hardness (~1000-1350 HV), excellent corrosion and oxidation resistance, and good wear resistance. Performs well in temperatures up to ~700°C.

- Balances wear resistance, toughness, and corrosion resistance, ideal for applications requiring durability in harsh, corrosive conditions.

- WC-Cr3C2-Ni

- A hybrid coating combining tungsten carbide and chromium carbide in a nickel or nickel-chromium binder

- Balances the extreme wear resistance of WC with the high-temperature and corrosion resistance of Cr3C2, with hardness typically between 900-1100 HV with HVOF, and 1200-1400HV with HVAF

- Cr3C2-NiCr

- Chromium carbide particles in a nickel-chromium binder. The NiCr binder enhances corrosion and oxidation resistance.

- High hardness (~800-1100 HV), excellent oxidation resistance up to ~900°C, and good corrosion resistance in harsh environments.

- Superior performance in high-temperature, oxidative, and corrosive environments, with moderate wear resistance.

Thermal Spray Coating Processes for Tungsten Carbide Coating

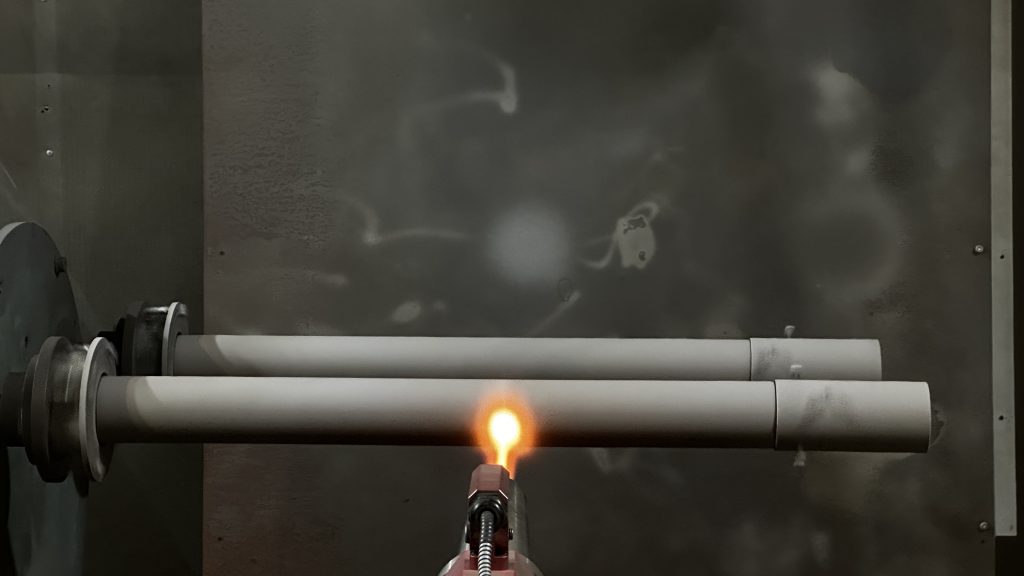

- High-Velocity Oxygen Fuel (HVOF)

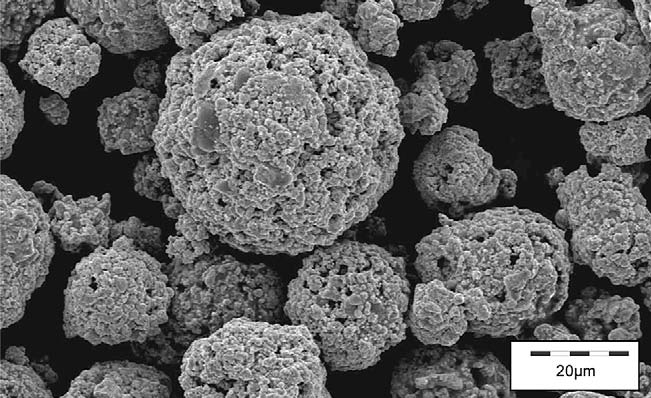

- HVOF uses a combustion process where oxygen and a fuel (e.g., kerosene, propane, or hydrogen) are ignited to create a high-velocity jet. Tungsten carbide powder is injected into this jet, heated to a semi-molten state, and propelled at supersonic speeds around 1000 m/s onto the substrate, forming a dense, tightly bonded coating.

- Produces carbide coatings with high density, excellent adhesion, and low porosity (<1-2%). Hardness typically ranges from 1000-1200 HV for WC-based coatings. Offers superior wear and moderate corrosion resistance.

- High particle velocity results in minimal degradation of carbide particles, preserving hardness and wear resistance. Ideal for WC-Co and WC-Co-Cr coatings in high-wear environments.

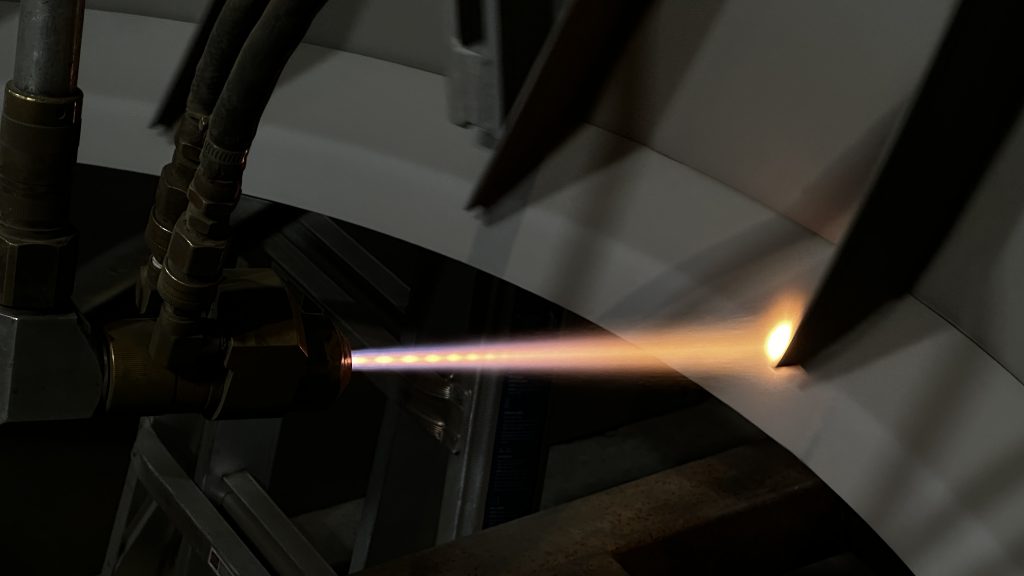

- High-Velocity Air Fuel (HVAF)

- Similar to HVOF, HVAF uses compressed air instead of oxygen, combined with a fuel (e.g., propane or natural gas), to produce a high-velocity, lower-temperature flame. Tungsten carbide powder is accelerated at high speeds (up to 1000-1500 m/s) to form a coating.

- Creates even denser carbide coatings than HVOF with lower porosity (<1%) and higher bond strength. Reduced thermal exposure minimizes carbide decomposition, resulting in harder coatings (up to 1500 HV for WC-based coatings). Improved corrosion resistance due to less oxidation during spraying.

- Lower flame temperature (compared to HVOF) preserves carbide integrity, enhancing coating durability. Cost-effective due to the use of air instead of oxygen. Well-suited for WC-Co, WC-Ni, and WC-Co-Cr coatings.

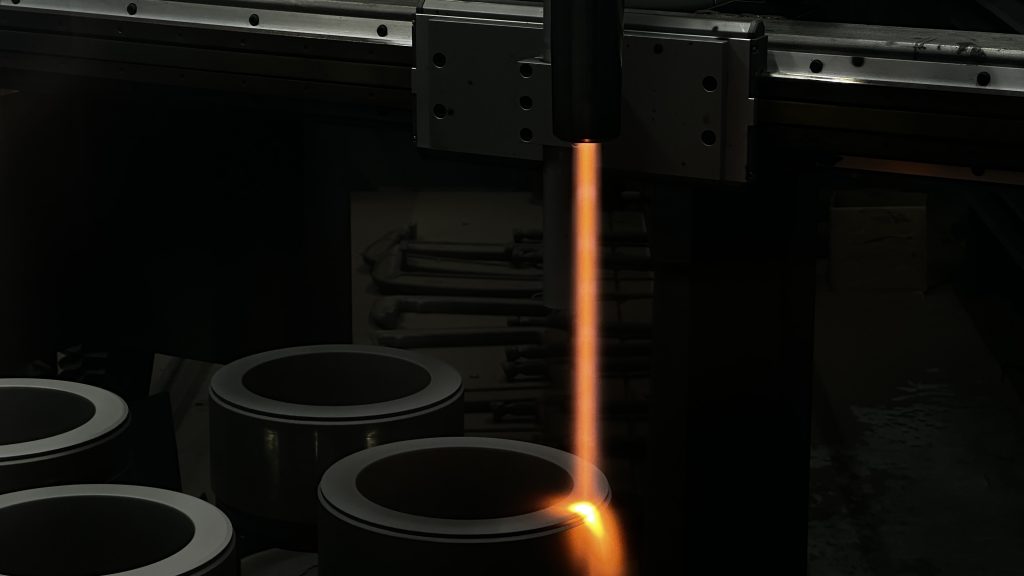

- Plasma Spraying

- Plasma spraying uses a plasma arc (generated by ionizing gases like argon or nitrogen) to create extremely high temperatures (up to 15,000°C). Tungsten carbide powder is injected into the plasma jet, melted or semi-melted, and propelled onto the substrate to form a coating.

- Produces coatings with moderate density and higher porosity (2-5%) compared to HVOF/HVAF. Hardness ranges from 900-1100 HV for WC-based coatings. Offers good adhesion and versatility for complex geometries.

- Higher porosity and lower bond strength compared to HVOF/HVAF can reduce wear resistance in extreme abrasive conditions.

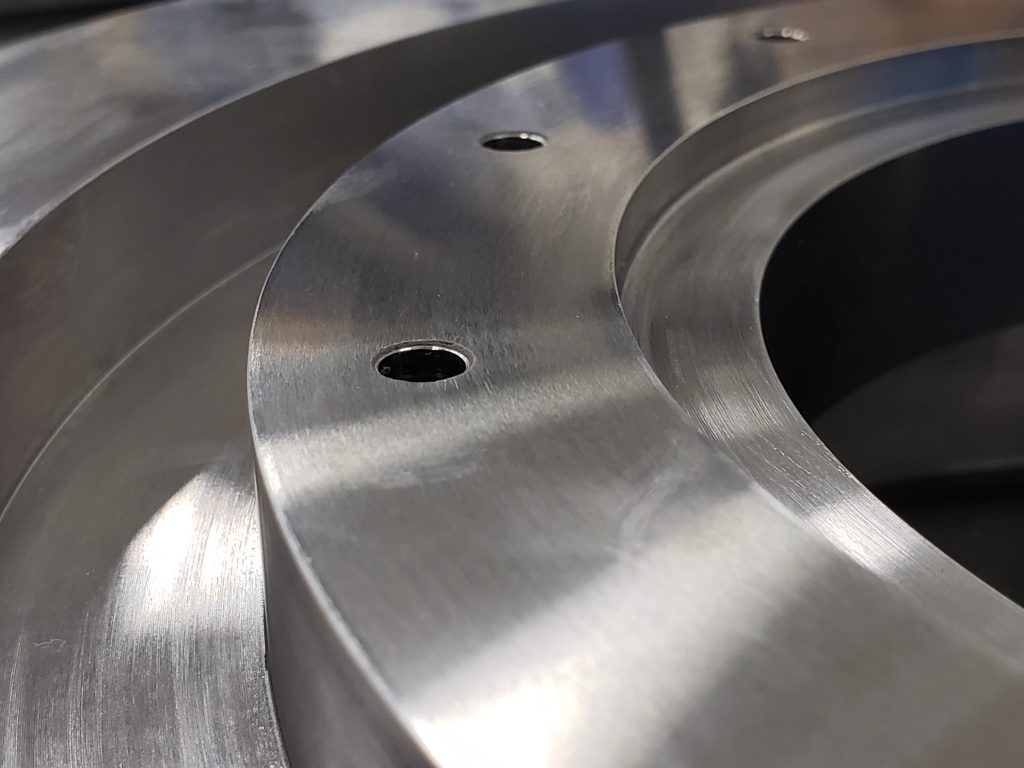

How Longevity Coatings Can help You

Longevity Coatings specializes in delivering high-performance tungsten carbide coatings tailored to meet your specific needs, enhancing component durability and performance across demanding industries. Utilizing advanced thermal spray processes like HVOF, HVAF, and plasma spraying, Longevity Coatings applies formulations such as WC-Co, WC-Ni, WC-Co-Cr, and WC-CrC-Ni, and many more to provide superior wear resistance, corrosion protection, and high-temperature stability. Whether you require coatings for aerospace components, or industrial machinery, Our expertise ensures precise application, maximizing component lifespan and reducing maintenance costs. By partnering with Longevity Coatings, you gain access to customized solutions that optimize performance in abrasive, corrosive, or high-temperature environments, ensuring reliability and efficiency for your critical applications.