At Longevity Coatings, we specialize in thermal spray coatings. Metal, carbide, and ceramic and more for industrial applications. Our decades of experience show the value of in-house control. Our Allentown, PA facility is a full-service hub, delivering fully manufactured, coated, and finished components.

We Offer

- CNC Machining: Precision crafting of titanium, stainless steel, and super alloy parts.

- Thermal Spray Coating: Expert application of carbide, ceramic, and specialty alloy coatings.

- Diamond Grinding: High-precision finishing for coated surfaces.

- Precision Flat Lapping: Ultra-smooth, flat surfaces with 4/alpha precision (4 light bands, ~0.000004 inches per band, Ra < 4 μin).

- Super Finishing: Mirror-like surface finishes (Ra < 4 μin) for optimal performance.

- Solid Ceramic Structures: Custom ceramic components for specialized needs

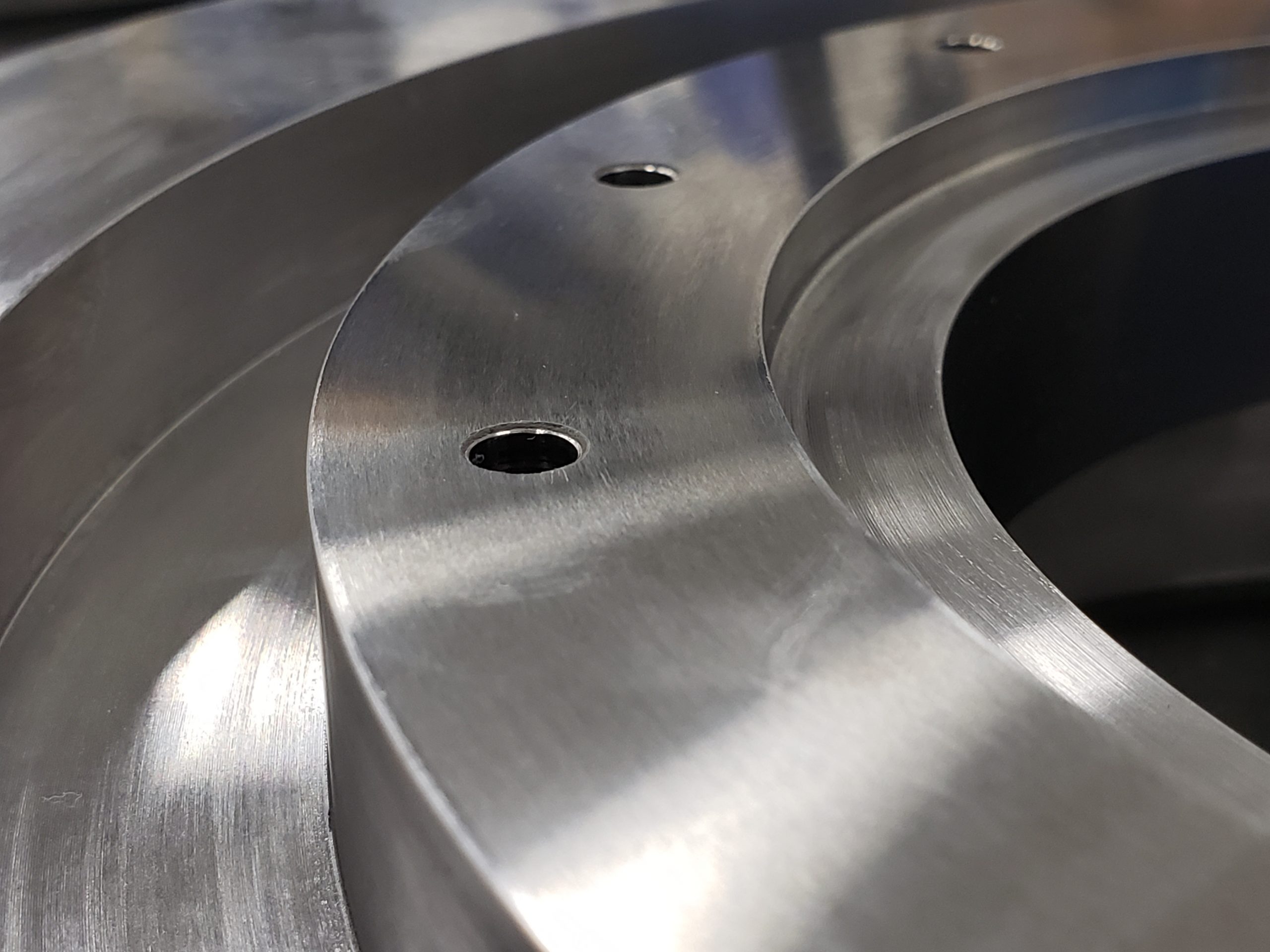

Grinding Services

We provide expert grinding services for all materials. With a focus on hard materials like tungsten carbide, ceramics, and hard-face alloys. We also grind coatings such as stainless steel, molybdenum, and more. Our advanced ID and OD universal grinders ensure precision, offering a complete manufacturing solution for your industrial needs.

Grinding Capacity

- OD Grinding 40″ diameter 118″ Length

- ID Grinding 40″ diameter 12″ Length

- Reciprocal Surface Grinding 12″ X 24″

- Rotary Surface Grinding 40″ Diameter 16″ Height

Machining Services

Our advanced CNC turning and milling centers produce tight-tolerance, complex component profiles with precision. We bring extensive expertise in working with traditional materials like steel and aluminum, as well as advanced materials, including titanium and super alloys. Ensuring exceptional quality and durability for your industrial applications.

Turning Capacity

- 38″ Diameter, in exes of 80″ Length

Milling Capacity

- 20″ X 40″ X 20″ Height

Ancillary Services

In our diamond grinding, honing and lapping shop, we readily meet your most demanding specifications for size and surface finishes:

- Carbides ground and lapped to an extremely smooth 1 Ra surface finish

- Plasma sprayed ceramics ground and lapped to a very fine 4Ra surface finish

- Diameter tolerance to .0001” (.0025mm)

- Solid carbide and ceramic parts

Flat Lapping capacity

- 36″ diameter

Large Handling Capacity

Whether your project calls for a small wear part or a large component, a limited production run or a large run, Longevity Coatings can handle the assignment. Our largest coating handling system can swing parts in excess of 18’ at a diameter of 50″. In addition, our multiple, medium and small, specialized coating handling systems can accommodate high volume parts processing. Multi-axis computer-directed motion control systems as well as mechanical multi-spindle setups provide the handling apparatus for processing shafts, sleeves, hubs, balls, and numerous other coating applications.