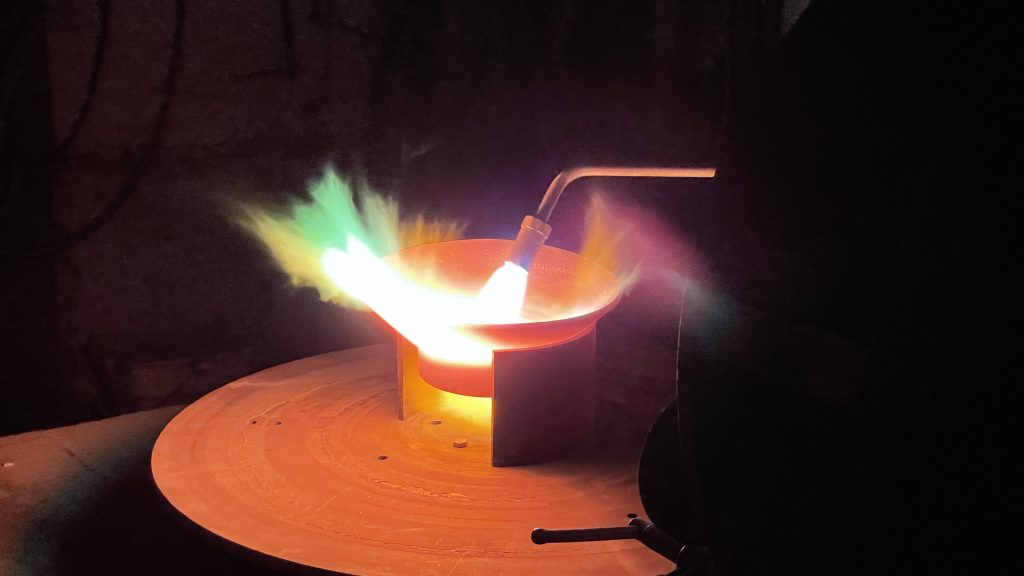

Diffusion Bonding (Spray and Fuse Coatings)

At Longevity Coatings, our fused coatings, created through diffusion bonding, enhance industrial components with exceptional durability and corrosion resistance. Applied via thermal spray and heat-treated at our Allentown, PA facility, these coatings serve many industrial applications.

Diffusion-Bonded Process

- We thermally spray metals or alloys (e.g., nickel, cobalt-based) and use heat treatment (1,800–2,200°F) to diffuse atoms, forming a seamless, metallurgically bonded coating.

Superior Impact Resistance

- The metallurgical bond provides stronger adhesion than other processes (e.g., HVOF, plasma spray), allowing coatings to withstand high-impact loads without delamination, ideal for applications where moderate impact is associated.

Enhanced Durability

- Fused coatings offer hardness (600–800 Vickers) and corrosion resistance, extending component life in harsh environments.

Types of Self-Fluxing Alloys for Spray and Fuse Coatings

Ni-Cr-B-Si

- Properties: Corrosion resistance, hardness (50–60 HRC post-fusion)

Ni-Cr-Mo-B-Si

- Properties: Enhanced corrosion resistance, hardness (58–63 HRC)

Ni-Cr-B-Si-Wc

- Properties: High wear resistance with addition of tungsten carbide particles, hardness (60–65 HRC)

Co-Ni-Cr-W-B-Si

Many more

At Longevity Coatings, we deliver spray and fuse coatings that excel in many industrial applications. Our Allentown, PA facility offers unmatched expertise and precision.

Tailored Solutions

- We customize coatings to meet your needs, ensuring durability for your components.

Proven Expertise

- Decades of thermal spray experience ensure reliable, high-quality results.

Full-Service Manufacturing

- Our Grinding, CNC machining, Precision flat lapping and super-finishing, provide tight tolerances and smooth finishes all in one manufacturing facility.